GXM Shelf Factory storage products

May 19,2025

GXM Shelf Factory has emerged as a prominent manufacturer dedicated to the design, production, sales, and service of warehouse shelving solutions. Our commitment to rigorous quality control and exceptional customer service has earned us a reputation for excellence among our clients.

Industrial Warehouse Heavy Duty Steel Racking are suitable for those who want to store heavy items, our heavy duty warehouse racks can be produced in different sizes, colors and load bearing. The load capacity of heavy duty pallet steel frame is usually 1000-5000 kg or even heavier. Three types of shelves can be choose: steel mesh, steel plate, wooden. The height of each layer can be adjusted by itself, and the end and end can be connected infinitely to save costs.

| Product attribute | |

| Product name | heavy duty rack system warehouse storage |

| Size | L2300*W1000*H2550mm ( As your request ) |

| Usage | Warehouse/Supermarket/Industry storage rack & shelf |

| Specification | This rack can be safe to keep goods. The space and load capacity for each tier are more large than common commercial Different thickness,size,layers,and colors are available for you to choose. |

| Others | Minimum order quantity: 10 sets Supply ability:5000 pieces per month Payment terms: 30% deposit upon signing the contract,the balance will be cleared by T/T before delivery. Delivery Terms: Upon factory Delivery Time: 10-15 workday upon receipt of the deposit |

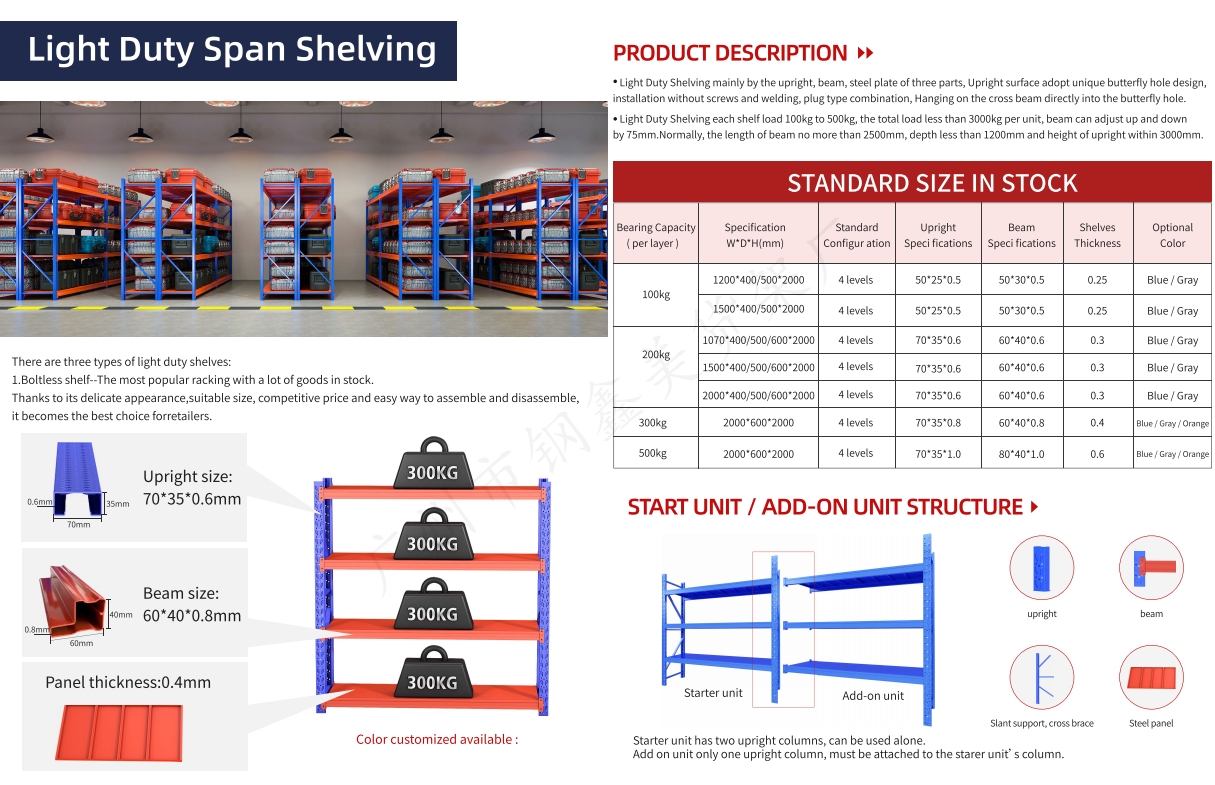

Capacity |

(KG/Layer) mm | Size(L*W*H) | Material Thickness |

| GXM653 |

100KG

| 1200*400*2000 | Column/Beam 0.6mm; Layer 0.3mm |

| GXM655 | 1200*500*2000 | ||

| GXM667 | 1500*400*2000 | ||

| GXM669 | 1500*500*2000 | ||

| GXM671 | 200KG | 1075*600*2000 | Column/Beam 0.7mm; Layer 0.3mm |

| GXM673 | 1500*400*2000 | ||

| GXM675 | 1200*400*2000 | ||

| GXM677 | 1200*600*2000 | ||

| GXM679 | 1500*500*2000 | ||

| GXM681 | 2000*400*2000 | ||

| GXM683 | 1500*600*2000 | ||

| GXM685 | 2000*500*2000 | ||

| GXM687 | 2000*600*2000 | ||

| GXM689 | 300KG | 1500*600*2000 | Column/Beam 0.9mm; Layer 0.4mm |

| GXM691 | 2000*600*2000 | ||

| GXM693R | 500KG | 2000*600*2000 | Column/Beam 1.1mm; Layer 0.5mm |

| Layers : | 4 | ||

| Color : | Blue / Orange / Grey-white | ||

| Other size and color can be customized based on the quantity of order. | |||

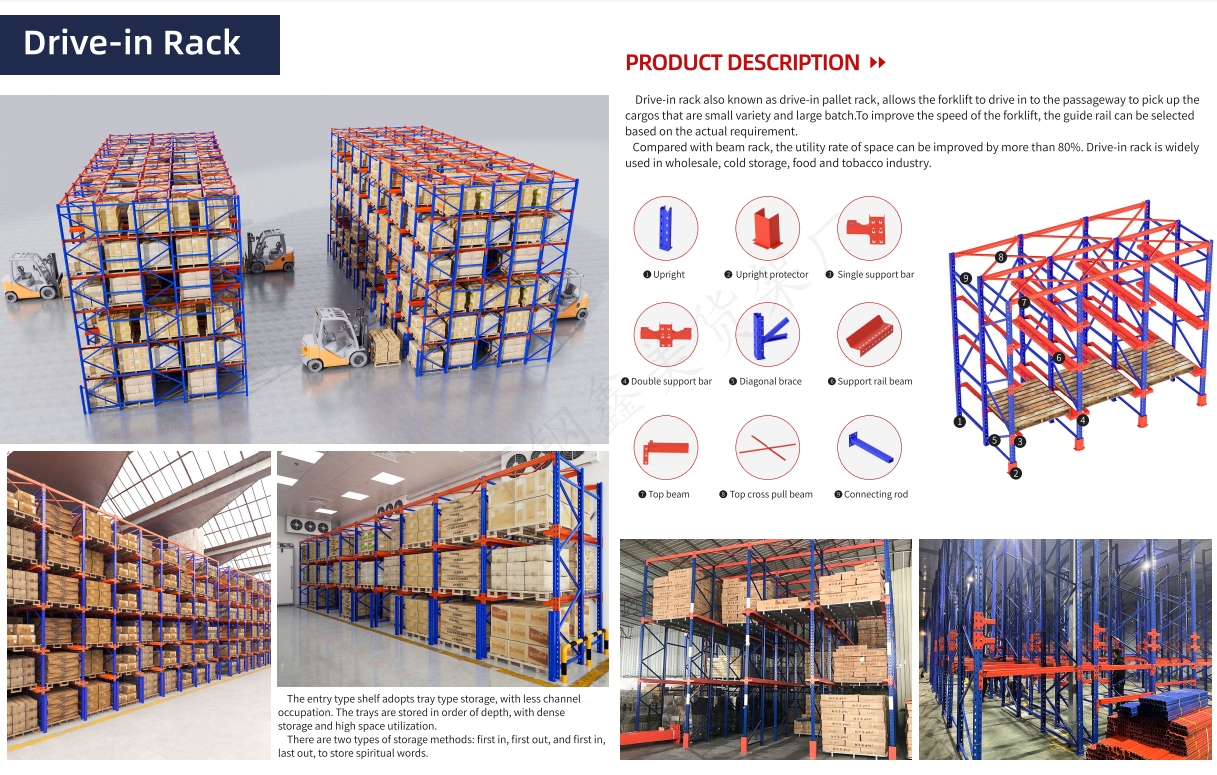

Drive-in racking is a type of warehouse storage system designed to maximize space utilization by allowing forklifts to enter the storage aisles and operate within the rack structure. This system is characterized by a series of deep lanes where pallets are stored in a last-in, first-out (LIFO) configuration.

Key features of drive-in racking include high-density storage, as pallets are stored in close proximity to each other, and a focus on storing a large quantity of homogeneous products. This system is suitable for items with a low turnover rate, as it may take more time to access specific pallets due to the LIFO configuration.

Drive-in racking is a cost-effective solution for warehouses with a large volume of pallets of the same SKU (stock-keeping unit) and limited space, as it minimizes the need for multiple aisles.

Cantilever rack is formed by upright, cantilever arm and connected rod. Thanks to its cantilever has strong load capacity with light and handy structure, it is very suitable for storing long materials, ring materials, sheets, tubes and irregular goods so that it can largely improve warehouse utilization. Cantilever rack is suitable for the warehouse with small space and low density.Since it is convenient to manage, it is widely used in mechanical processing industry and building materials industry. The height and weight of the product determine whether the cantilever rack needs to be light or heavy duty.Both systems offer the possibility of locating storage levels on one side or both sides of the structure.

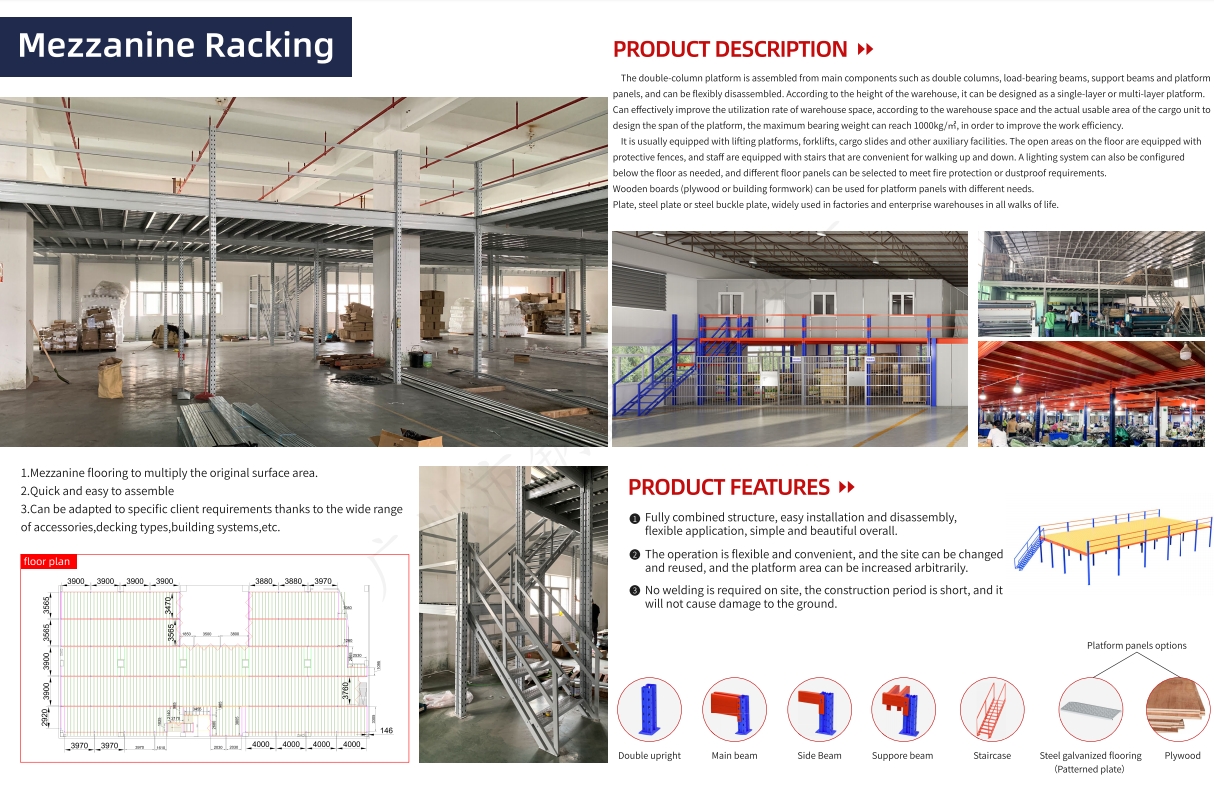

ezzanine racking is a storage solution that involves the construction of an intermediate level or platform within a warehouse or storage facility. This platform creates additional space above and below it, effectively doubling the available storage area.Mezzanine racking systems are often used to optimize vertical space and are supported by a structural steel framework. These systems provide a cost-effective way to maximize storage capacity without the need for facility expansion. Mezzanine racking is commonly employed in various industries, including logistics, manufacturing, and distribution, to enhance efficiency and organization within a given space.

PREVIOUS:

NEXT:

Contact Us

E-mail:

gxmshelf@gmail.com

Phone/WeChat:

+86-13902490286

Address:

No.151GangshenRoad,ShuanggangVillage,JianggaoTown,BaiyunDistrict,GuangzhouCity,GuangdongProvince

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

No.151GangshenRoad,ShuanggangVillage,JianggaoTown,BaiyunDistrict,GuangzhouCity,GuangdongProvince